Implementing a digital strategy can enable part manufacturers of all sizes to take greater advantage of automation,adopt 3D printing for production, and ultimately expand into new market opportunities and reduce time to delivery. In order to remain competitive, many part manufacturers look to digitalization, which connects all of the steps of part manufacturing planning and production with a single source of information, or a digital thread.

Part manufacturers continue to face added pressures from changing market expectations, with customers who require improved accuracy and faster response times. The latest version of NX continues to support end-to-end solutions for additive manufacturing, helping manufacturers realize the goal of using 3D printing for industrial production.

Siemens nx latest version software#

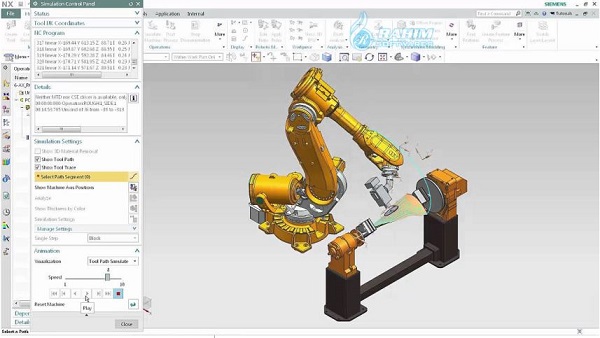

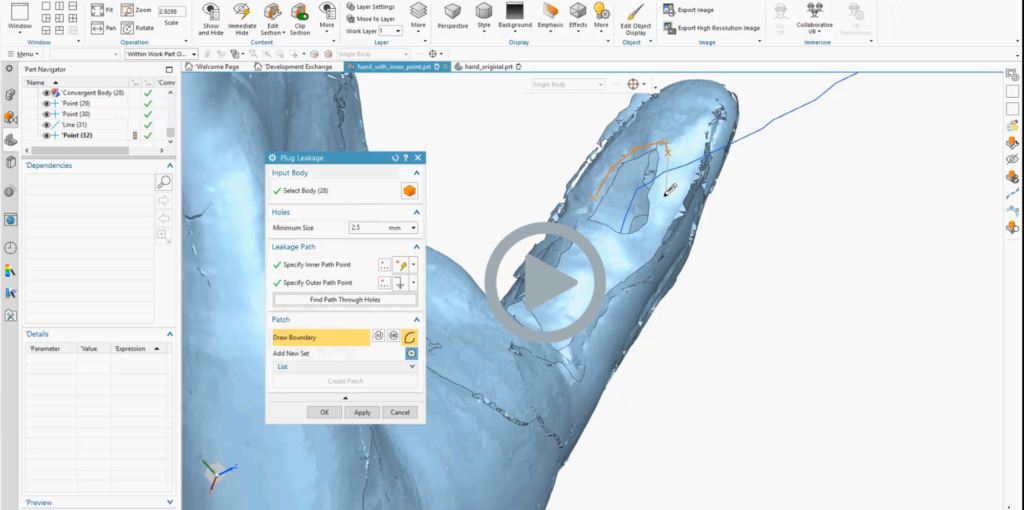

The new NX Machining Line Planner tool, combined with integrated NX CAM software for feature-based machining, provides new capabilities for industries with high-volume production of complicated parts, such as automotive and industrial machinery. Advanced automation capabilities for computer- aided manufacturing (CAM), including robotic programming, adaptive milling, and tooling design, provide innovative, industry-specific technology to help deliver high- quality products to the market in less time. Visit the NX Manufacturing community to learn more about What’s New in NX for Manufacturing.The latest version of Siemens’ NX™ software unites the next generation of tools for additive manufacturing, computer numerical control (CNC) machining, robotics and quality inspection to enable the digitalization of part manufacturing within a single, integrated, end-to-end system. NX is part of the Xcelerator portfolio, Siemens’ integrated portfolio of software, services and application development platform. Integrated in NX CAM and with more than 1,000 postprocessors, Post Hub can help manufacturers generate programs for a wide range of CNC machine and control configurations. Post Hub is a new, cloud-based solution for postprocessing that enables a streamlined process to generate production-ready CNC programs. It supports the HP MJF 5200 and HP MJF 540 color series. The new Siemens HP MJF Build Processor enables printing of color parts directly out of NX, without the need for 3rd party build processors, according to the company. NX Additive Manufacturing facilitates the process from design model to printed part with integration that eliminates the need to convert and remodel parts between applications. Robotic programming now enables users to program and simulate multiple robots to perform machining tasks such as drilling, deburring and polishing. 5-Axis Guiding Curves finishing has been enhanced to include parametric tool-axis interpolation, providing more control for surface finish. NX CAM software ’s new 5-Axis Adaptive Milling, an advanced roughing strategy, enables high material removal rates using fewer setups resulting in shorter machining times. Siemens Digital Industries Software, Plano, Texas has released Siemens’ NX for manufacturing software, an end-to-end solution for part manufacturing that can accelerate machining, program multiple robots, print color parts, and generate production-ready CNC programs using a cloud-based technology, according to the company.

0 kommentar(er)

0 kommentar(er)